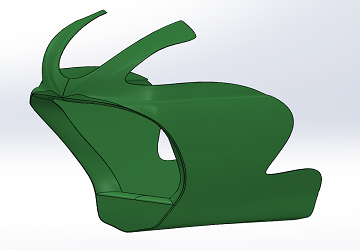

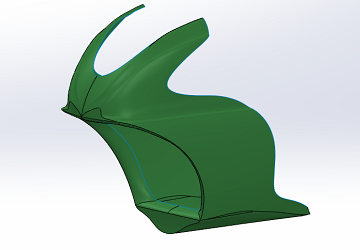

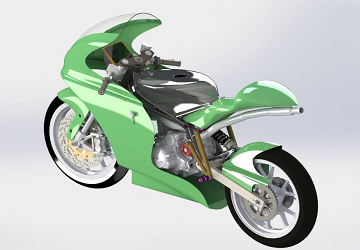

Fairing First Concept

First approach to the design of the motorcycle fairing.

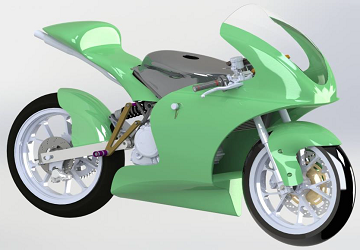

The parts for the motorcycle's bodywork were modelled using surface design in Solidworks. Inspiration for the parts was taken from teams competing in MotoGP's Moto3 category, which share similar specs with the MotoStudent competition. The prototype's design was optimised analysing data from CFD simulations ran in Ansys Fluent (check Motorcycle Wind Tunnel Simulation for Motochanics-UA).

In this section it is possible to see a compilation of pictures featuring the design of the MotoStudent 2019 edition's motorcycle. Pictures range from design concepts to the final product.

First approach to the design of the motorcycle fairing.

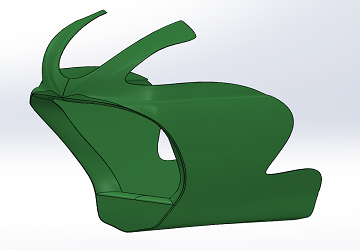

With Design for Manufacturing in mind and aerodynamic performance, the first concept's design evolved.

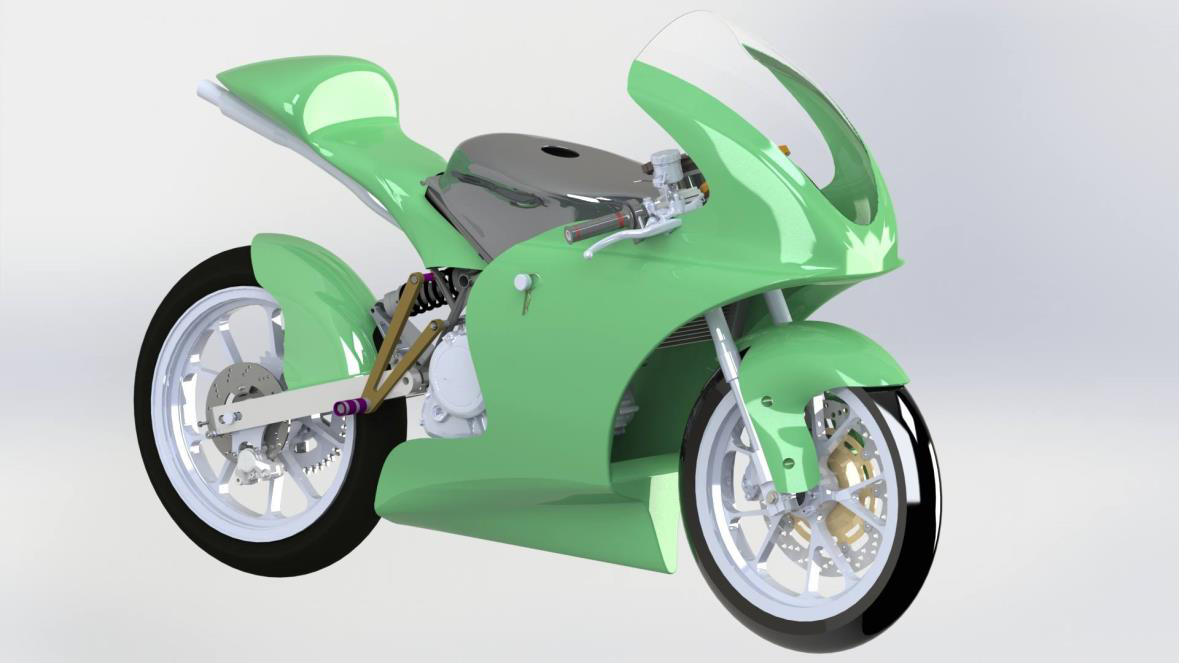

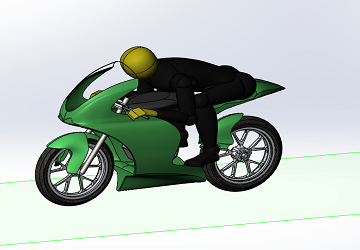

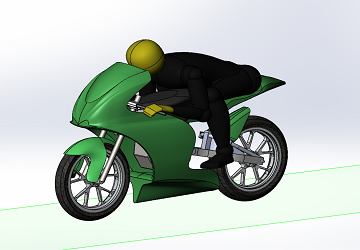

The first bodywork assembly of the 2019's edition.

Small updates on the geometry to upload for CFD simulations.

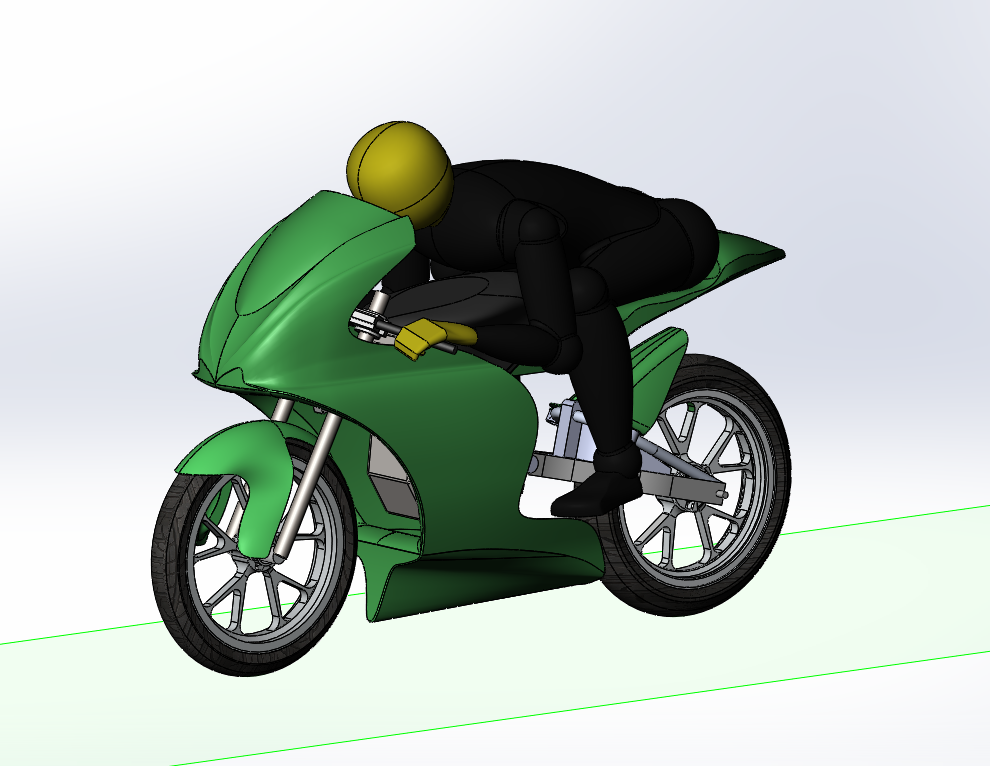

Complete CAD assembly of the Motochanics 2019's prototype.

Complete CAD assembly of the Motochanics 2019's prototype.

The prototype displayed at Motorland Aragón.

The first real challenge as a mechanical design engineer. To research and develop a complex competitive prototype that is limited to a tight budget and manufacturing operations. It was proof that a small team can build a performance prototype when synergy is at its best. Finally, it was an honor to become the first portuguese team to ever fully complete a Motostudent edition, not only being able to finish the entire race but also with a very good result!

3D CAD; CAE

Failure Mode and Effects Analysis

Design for Manufacturing & Assembly